Facilities

The facilities of OLT MOTOR consist of:

- Pad saw for sections of max 240mm MEBA SWING

- Plant for manual air sheet cutting

- Welding machines MIG-MAG, TIG-WIG, MILLER

- Lathe SN400 2 pcs

- Lathe SN320 1 pcs

- Universal mill 1 pc

- Tapered mill 2 pcs

- Nibbling machine 2 pcs

- Processing centres with numeric control, lathe OKUMA LB2000, LB3000, Lathe GENOS, Lathe OKUMA ES.

- Lathe with 2 turrets and 2 universal with 3 axes, OKUMA LT200 TWIN STAR

- Possibilities of bar lathing with drilling, threading

- Bridge crane 4 tonnes

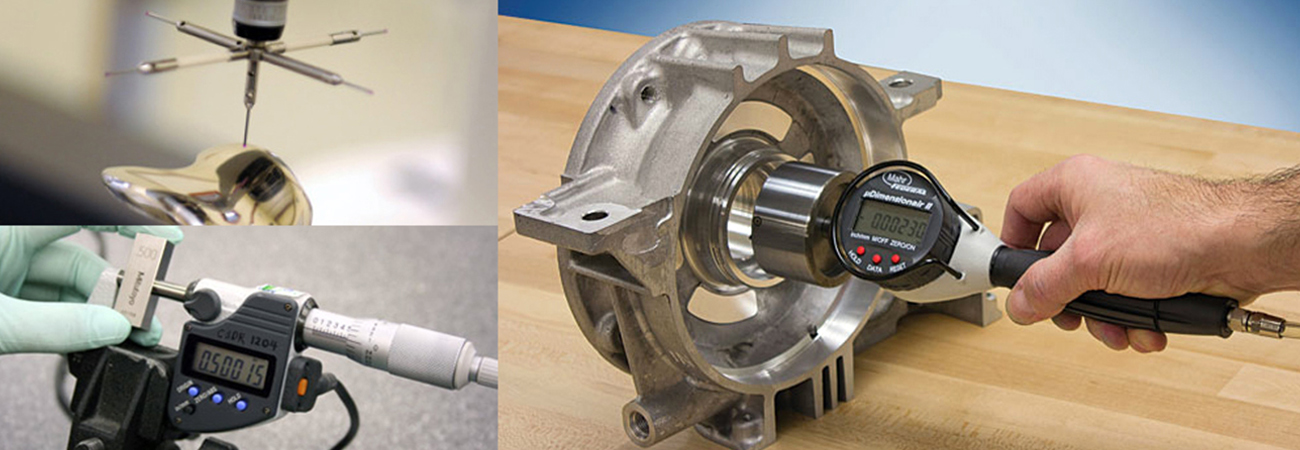

- TESA vertical measurement

- Therma treatment oven with sizes 600x600x600

You can find us at:

SC OLTMOTOR N2006 SRL

Adress:

17 bis, Gr. Alexandrescu st.

Telephone:

+40.745 145 606

+40.744 778 033

+40.723 301 702

+40.744 778 033

+40.723 301 702

Fax:

+40.249 435 585

Email:

george@oltmotor.ro

elena@oltmotor.ro

oltmotor@yahoo.com

elena@oltmotor.ro

oltmotor@yahoo.com