About us

SC OLTMOTOR SRL is a company with full private capital and its main activities are as follows:

1. Mechanic and chip removal processing:

On lathes with numeric control (we have 6 lathes with numeric control brand OKUMA);

On conventional lathes SN 400, SN 320;

Universal milling machines;

Drilling machines;

Grinding and sharpening machines;

Nibbling and bending machines;

99 percent of the parts and sub-ensembles that we make on these machines are performed following the client’s technical documentation according to the technological flow pre-established for each benchmark according to their technical characteristics.

The checking and size control shall be carried out according to the control plan made available either by the client or implemented by us.

The packing and transport of the parts manufactured in the factory’s workshops shall be carried out according to the client’s precise indications.

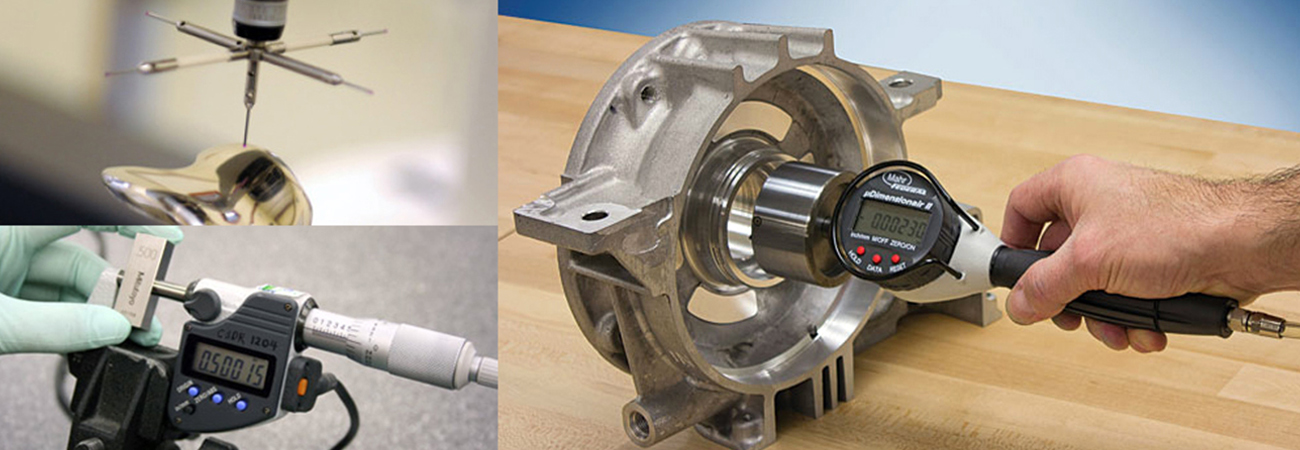

The company has arranged a size control workshop fitted with specific measurements and control devices.

- Gage kits; micrometers, callipers;

- vertical control device;

- control 3 D (by collaboration), roughness tester;

- certain devices regarding the subject of the type verifiers of exterior, interior threads, calibres for holes, diameters, lengths.

The company holds a thermal treatment workshop and skilled personnel for thermal treatments!

2. Manufacturing of mechanic-welded sub-ensembles

For the carrying out of the mechanically welded parts we hold cutting machines -plasma, mechanic saw, welding technologies TIG, MIG MAG, WIG, the sub-ensembles being carried out following the technical documentation of the client in compliance with the technological processes from the quality manual provided by certification ISO 9001 that we hold!

We perform on order steel and stainless steel metallic structures!

- Industrial halls;

- Metallic structures of the type industrial metallic shelves, industrial containers, structures for advertising boards, various basins for industrial uses, steel brackets, fixing devices, welding devices, various structures!

We provide the quality and precision required by the documentation by skilled and specialised personnel.

- stainless steel structures on demand - closets, tables, shelves, brackets, stainless steel stairs, stainless steel hand rails;

- aluminium welded structures – we perform by means of welding various aluminium welded devices by TIG procedure with protecting gas (argon) namely brackets, containers, frames made of aluminium; aluminium tanks!

- We recondition aluminium parts for the automotive industry namely oil tanks, gearbox cases, aluminium protection bars, radiators, aluminium rims, aluminium pump covers, other mechanically destroyed benchmarks.

1. Mechanic and chip removal processing:

99 percent of the parts and sub-ensembles that we make on these machines are performed following the client’s technical documentation according to the technological flow pre-established for each benchmark according to their technical characteristics.

The checking and size control shall be carried out according to the control plan made available either by the client or implemented by us.

The packing and transport of the parts manufactured in the factory’s workshops shall be carried out according to the client’s precise indications.

The company has arranged a size control workshop fitted with specific measurements and control devices.

- Gage kits; micrometers, callipers;

- vertical control device;

- control 3 D (by collaboration), roughness tester;

- certain devices regarding the subject of the type verifiers of exterior, interior threads, calibres for holes, diameters, lengths.

The company holds a thermal treatment workshop and skilled personnel for thermal treatments!

2. Manufacturing of mechanic-welded sub-ensembles

For the carrying out of the mechanically welded parts we hold cutting machines -plasma, mechanic saw, welding technologies TIG, MIG MAG, WIG, the sub-ensembles being carried out following the technical documentation of the client in compliance with the technological processes from the quality manual provided by certification ISO 9001 that we hold!

We perform on order steel and stainless steel metallic structures!

- Industrial halls;

- Metallic structures of the type industrial metallic shelves, industrial containers, structures for advertising boards, various basins for industrial uses, steel brackets, fixing devices, welding devices, various structures!

We provide the quality and precision required by the documentation by skilled and specialised personnel.

- stainless steel structures on demand - closets, tables, shelves, brackets, stainless steel stairs, stainless steel hand rails;

- aluminium welded structures – we perform by means of welding various aluminium welded devices by TIG procedure with protecting gas (argon) namely brackets, containers, frames made of aluminium; aluminium tanks!

- We recondition aluminium parts for the automotive industry namely oil tanks, gearbox cases, aluminium protection bars, radiators, aluminium rims, aluminium pump covers, other mechanically destroyed benchmarks.